FITZGERALD HURLEYS

OUR PROCESS

As any quality hurleymaker will tell you, the birth of any good hurley begins in the wood.

At Fitzgerald Hurleys, we only use the best quality natural material – ash being by far the most suitable timber for hurleys due to its natural strength, flexibility and its unmatched capacity for shock absorbency. But any old ash won’t do. That is why we carefully select ash trees with the most suitable root structure for hurleymaking – offering the naturally curved grain that gives essential durability to the bas. The correct felling of the ash tree is also extremely important to gain maximum yield.

After the trees have been expertly felled, they are brought to our sawmill in Araglen, Co. Cork. Having our own sawmill is a great advantage as it means we can manage and oversee the sawing process, making sure we delicately cut each butt to guarantee top quality grain on each hurley plank.

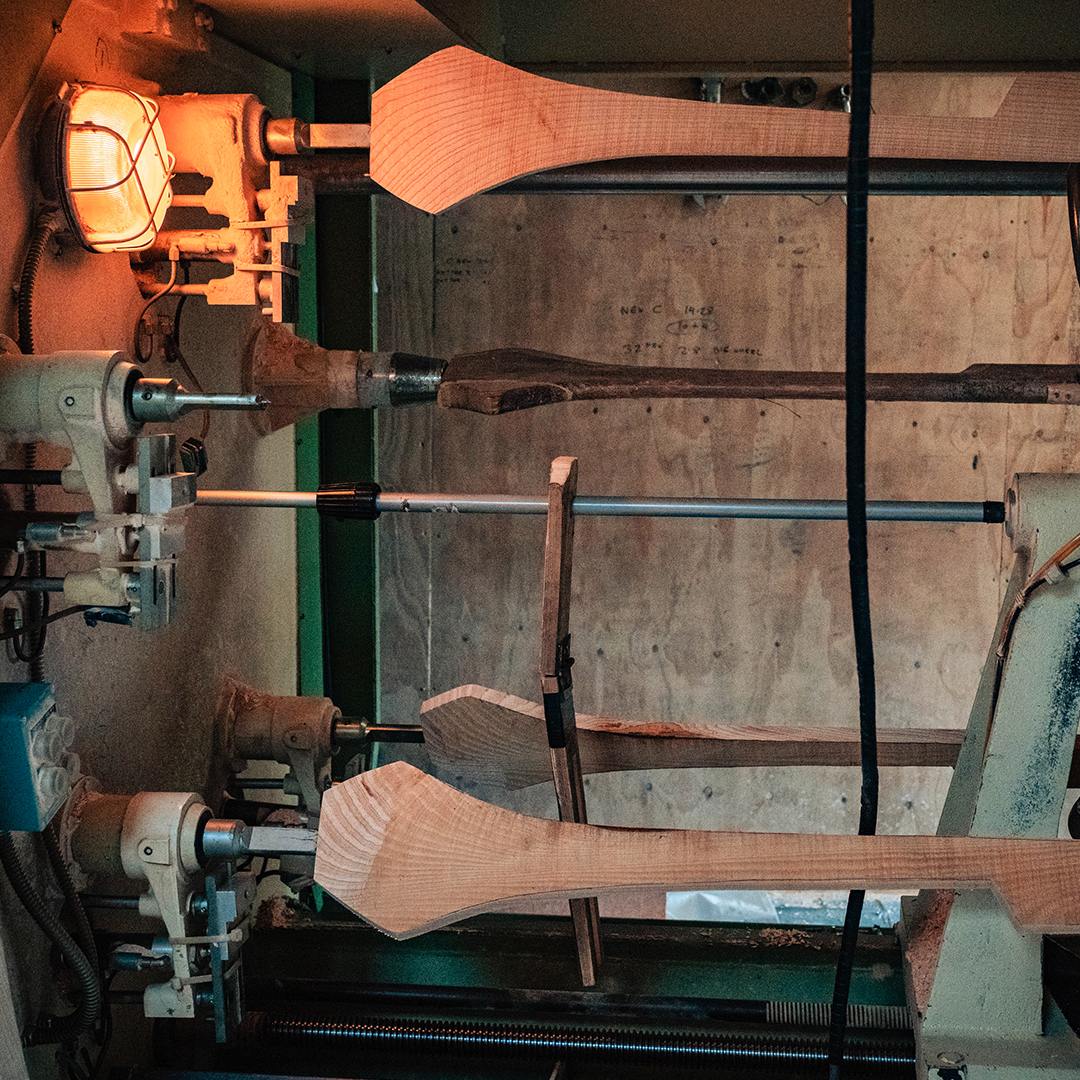

From there the planks are dried until optimum moisture content is reached, enabling the start of the manufacturing process. Our state-of-the-art machinery is programmed to cut and outline the shape of the hurleys, after which our team sand and spokeshave each hurley by hand to suit each customer’s requirements. Our proven manufacturing process, high-grade materials, and the artisan craftmanship used to finish our product means that when you see the Fitzgerald Hurleys logo, you can be sure you are receiving the very best of quality.